When it comes to energy use, most of us don’t pay much attention to how much we consume, waste, or could potentially save. Part of the problem is a lack of visibility — without easy access to real-time data, it’s hard to understand the impact of our habits or feel motivated to change them.

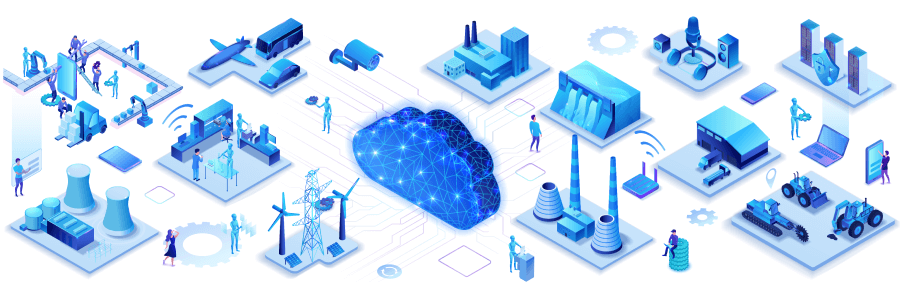

Fortunately, the progress doesn’t stand still. With the emergence of IoT, collecting and analyzing data has become much easier and quicker than ever. With this technology, we now have the ability to track energy consumption at every level, from individual appliances in our homes to entire industrial systems.

But one does not simply use technological benefits without complexities and risks — the IoT development has its intricacies, better to be aware of before you initiate it. In this blog post, we discover the role of IoT in the energy sector: how it contributes to the “green concept” shift, and why data security is an Achiless’ heel of technology usage.

Key Highlights

- IoT devices go far beyond smart homes — they’re essential at the industrial level for preventing grid overloads and enabling smarter energy consumption.

- Wired IoT systems provide stability; wireless backups offer resilience. A hybrid model is key for industrial energy IoT setups.

- Isolated “air-gapped” networks keep critical infrastructure safe from cyber threats, even at the cost of limited remote access.

- Integrating thousands of sensors into legacy systems takes planning, especially when hardware, software, and vendors vary.

Not Only Household Usage: Going Beyond the Concept of a Smart House

These days, the idea of an IoT smart home solution filled with sensors and devices controlled with just a few taps on an app can’t already be called surprising. But what if we broaden this scope and consider the concept of smart districts, cities, or even countries?

A vivid example of this forward-thinking approach can be seen in the United Arab Emirates. The country has adopted a comprehensive strategy that goes far beyond just housing and communal energy use. For example, the UAE has implemented a unified system that stores detailed architectural and electrical plans for every building in the country, essentially creating a centralized digital map of the national energy infrastructure.

This level of integration delivers tangible results. With such a detailed and interconnected system, powered by data from IoT sensors, the government can track energy usage down to individual sockets in private apartments. Haphazard data are transformed into clear and informative graphs and analytics.

As a result, the government is equipped not only to monitor and manage the current energy infrastructure more effectively, but also to plan future development with precision, at the scale of an entire nation.

IoT devices monitor energy consumption by using sensors that collect real-time data from appliances, equipment, or entire systems. These sensors track parameters like power usage, voltage, current, and operational status. The data is then transmitted, often wirelessly or through wired networks, to centralized platforms where it’s analyzed and visualized. This continuous monitoring enables users to identify usage patterns, detect inefficiencies, and optimize energy consumption for cost savings and sustainability.

Green Energy Shift and How IoT Contributes to the Change

Using IoT sensors to collect data from electric meters is nothing new. But as more people become not just consumers but also producers, the role of these devices is evolving and becoming far more critical.

Why does this matter? Traditional electrical grids were designed under the assumption that households only consume energy. The biggest challenge used to be measuring usage accurately so the network could balance loads and avoid undercapacity issues. Dedicated software handled this well.

But things changed with the rise of green energy. Solar panels and wind turbines are now everywhere, including even individual homes. This shift introduced a new challenge: excess energy. And while having more energy might sound like a good thing, it’s not that simple.

Read about Industrial IoT for Sustainability to Surpass Your Environmental Goals

Grids built for consistent demand aren’t equipped to handle sudden surpluses. If one household overproduces, it’s manageable, since automation can simply shut the source off. But when entire neighborhoods or regions feed more energy into the grid than it can absorb, the risks grow.

At best, this leads to plummeting energy prices. At worst, it causes system instability or even outages, especially if automation fails. And since many control mechanisms are baked into privately owned generation equipment, utility companies often have no way to intervene.

And here’s an extensive field of activity for various IoT devices. Companies working with the technology strive to resolve these threats by creating sensors that are able to control local energy consumption and generation, and interact with equipment produced by different vendors.

IoT plays a crucial role in managing renewable energy by enabling real-time monitoring and control of energy generation and consumption. As more households and facilities produce energy through solar panels, wind turbines, and other green sources, IoT sensors help track energy flows to prevent grid overloads caused by sudden surpluses.

These devices allow smart balancing of supply and demand, ensuring stable and efficient integration of renewable energy into existing grids. Additionally, IoT supports data-driven planning and maintenance, making renewable energy systems more reliable and scalable.

Playing the Leading Role at the Industrial Level: Why It’s All about IoT

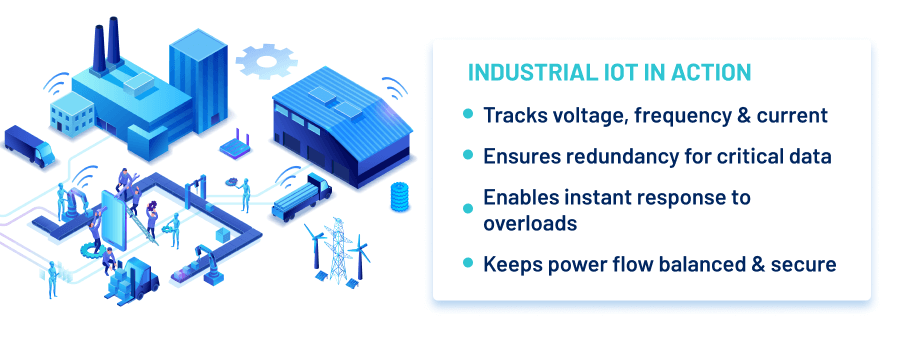

Now, let’s shift from managing household-level IoT power consumption and generation to a more complex application of IoT — energy transfer at the industrial scale. Unlike the basic sensors and automation tools used in homes, industrial environments rely on specialized IoT devices that perform far more sophisticated functions, particularly within large facilities like power plants.

They track key parameters such as current type, voltage levels, frequency oscillations, and redundancy status, enabling operators to respond instantly to irregularities, prevent overloads, and maintain a stable balance across energy flows.

Naturally, such a variety of critical aspects brings up concerns about the reliability and security of the entire system, which calls for robust safeguards and thoughtful design.

Take a power plant, for example. To ensure an uninterrupted and accurate IoT energy monitoring system, redundancy must be built into it. From here stems the fact that it’s not enough to install a single sensor to track something as vital as voltage. Each critical parameter should be monitored by at least two devices, so that if one fails, the other continues to deliver real-time data.

Check out How IoT Embedded Systems Are Impacting Industries

Wire or Wireless Data Transfer? Both!

When it comes to energy management, especially at the industrial level, there is no margin for error. Security, precision, and reliability are non-negotiable; that’s why achieving full visibility across an energy facility is critical. This depends on consistent and accurate data collection from thousands of sensors distributed throughout the infrastructure.

But visibility is only as good as the data transfer methods behind it.

Reliable and uninterrupted data transmission is of paramount importance, and in complex environments like power plants, this becomes a challenge to tackle. While wireless communication has gained popularity due to its flexibility and cost-effectiveness, it’s not always the best fit for energy facilities. Why? All because of the unique conditions of these environments.

Power plants are high-interference zones where radio noise, electromagnetic fields, and structural obstructions can disrupt wireless signals. Relying solely on wireless channels in such settings could lead to data loss, delays, or vulnerabilities, which is unacceptable when dealing with critical energy systems.

This is the reason why such facilities as power plants use wire data transfer methods. Thousands of sensors scattered across it are usually connected, whether via an RS-485 standard or optical Ethernet, which represents a kind of industrial computer where the entire dataset is processed.

Hereby, this ecosystem is united into a local Ethernet-based network, where sensors interact through optical wires within the power plant.

Need to develop a future-proof, secure industrial IoT ecosystem?

CONTACT US!Does this mean that wireless data transfer channels are not applicable here at all? Apparently not. Although wires used to be a more reliable and secure option, nobody guarantees that they will serve forever. Mechanical damage, wear and tear, or unexpected infrastructure failures can compromise even the most robust cable systems. In scenarios where no wireless fallback exists, such incidents can lead to costly downtime with all its consequences.

That’s where wireless channels come into play, not as replacements, but as complementary backups or secondary layers of connectivity. They provide a degree of resilience that wired systems alone cannot offer. In fact, many modern energy facilities now implement wireless IoT networks in non-critical areas or use them to bridge connections in hard-to-reach or mobile components, ensuring continuity in data flow when the primary wired network is compromised.

Learn about 16 Types of Industrial IoT Sensors for Companies to Consider

Air Gap Concept or How to Ensure Bullet-Proof Security of your IoT Ecosystem with a Real-World Example

The topic of security of IoT for energy management is broad, but one critical area worth highlighting is the threat of external attacks. Today’s world can hardly be called stable and safe, and infrastructures like power plants are high-value targets. Not only for cybercriminals but also for state-sponsored hackers or even terrorist organizations. That’s why these facilities are typically designed with security at their core, and their networks are structured to be completely inaccessible to unauthorized users.

Dive into IoT Biggest Security Challenges for Businesses to Tackle

One key strategy employed is the creation of isolated data transfer networks — systems that are entirely cut off from the public Internet. This level of separation goes far beyond the protection offered by traditional firewalls. It’s a concept known as an air gap.

An air-gapped system ensures that there is no physical or logical connection between the operational network and external networks. This means that even if an attacker compromises a corporate or cloud-based system, the critical infrastructure remains untouched. While this setup can limit some remote monitoring and update capabilities, the trade-off is a much higher level of protection for the most sensitive parts of the energy grid.

Of course, challenges go beyond just monitoring and update limitations when introducing such secure, isolated systems. One of the biggest hurdles is integration. For instance, if a power plant wants to deploy new sensors to collect additional types of data, integration can quickly become a complex task. The difficulty lies in finding a vendor capable of ensuring seamless compatibility with the facility’s existing hardware and infrastructure — all while working within a network environment that lacks Internet access.

Take a look at the IoT Hardware Development Guide

Our company has hands-on experience implementing isolated IoT networks for industrial environments. One of our key projects involved a client that manufactures industrial computers for power plants. They engaged our team to develop specialized software for monitoring IoT sensors within a fully air-gapped system.

The goal was to enable real-time data collection and monitoring across various sensors, and include data visualization and tools for operators to automatically update firmware — all within a secure, offline environment.

Striking the Balance Between Data Availability and Security — Why Can’t Do Without a Sacrifice

Making decisions without data is like operating blindfolded. Data must be accessible to those who need it, yet protected from unauthorized access. This creates an inevitable tension between accessibility and security, especially in critical sectors like energy management.

The key challenge here is not choosing one over the other, but rather striking the right balance between the two, ensuring that data remains available for informed decision-making while maintaining the highest standards of cybersecurity.

Put simply, you want to collect data from as many sensors as possible. Meanwhile, exposing that data to the public web would be a serious security risk. The challenge becomes even greater when real-time data is required on a central server, yet some sensors are located in areas with no Internet connectivity.

A practical example from our own experience illustrates this well. We worked with a company that provides electric vehicle charging solutions. Our task was to develop a monitoring system capable of collecting and transmitting data from charging points deployed across diverse and sometimes remote locations with limited or no network coverage.

To overcome this, we implemented a solution that allowed data to be locally accumulated and then transmitted via the user’s mobile application when connectivity became available. This approach ensured periodic yet secure data delivery without relying on constant Internet access.

Growing Ambitions = Growing Complexities. Scalability Issues to Consider

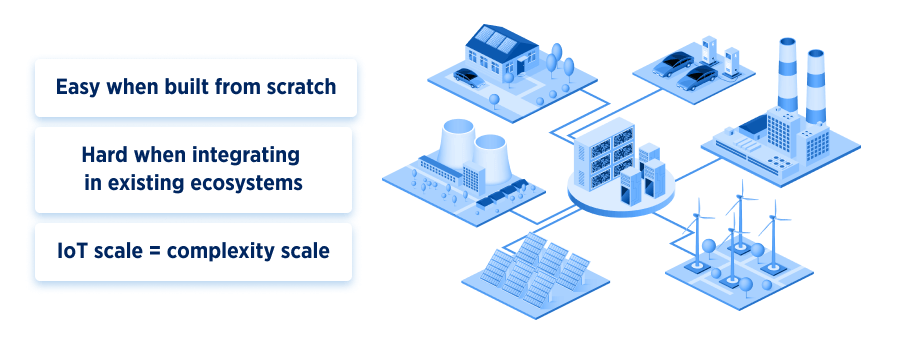

As we discussed earlier, the concept of a smart home, or even a smart residential district, is no longer groundbreaking. However, the larger the scale of your IoT initiative is, the more complex the challenges become. Integrating thousands of IoT sensors into an existing ecosystem is no small feat, especially when dealing with legacy systems, diverse hardware, and fragmented data protocols.

The successful example of the United Arab Emirates, mentioned at the beginning of this article, can be attributed to several key factors. First, their strong financial resources provided the foundation for large-scale innovation.

Second, and perhaps more critical aspect, they were able to build their cities from the ground up, often on undeveloped land. This gave them a significant competitive advantage: when starting from scratch, there’s no need to account for outdated infrastructure, conflicting systems, or incompatible vendors. Everything can be planned, designed, and implemented with cohesion from day one.

By contrast, in most parts of the world, scalability issues arise precisely because of the need to integrate new IoT systems with existing infrastructure. This includes working with multiple generations of hardware, various proprietary software platforms, and maintaining compatibility across a wide range of vendor technologies — all while ensuring minimal disruption and maximum security.

The cost of developing an IoT energy management solution varies widely depending on factors such as the scale of the project, complexity of integration with existing infrastructure, security requirements (like implementing air-gapped networks), and the types of sensors and data systems involved.

Industrial-scale solutions with advanced monitoring, redundancy, and cybersecurity features typically require a higher investment than residential setups. Custom software development, hardware compatibility, and ongoing maintenance also influence the overall cost. For an accurate estimate, it’s best to consult with an experienced IoT solutions provider who can tailor the project to your specific needs and goals.

Wrapping Up

The integration of the Internet of Things in energy management has already become a present-day necessity. Whether it’s helping people track their home energy use or allowing engineers to monitor massive industrial systems in real time, IoT is quietly transforming the way we generate, manage, and consume energy.

But, of course, it’s not all smooth sailing. As powerful as these technologies are, they come with real challenges. From keeping sensitive data safe, to making sure new sensors work well with old systems, to figuring out how to scale without losing control — it all requires careful planning and a thoughtful approach.

That’s why it’s important to partner with a vendor who has proven expertise in IoT implementation — someone you can trust to navigate the technical challenges. Our team has hands-on experience delivering secure, scalable IoT solutions in complex environments, from energy facilities to remote infrastructure. Drop us a line, let’s build your future-proof ecosystem together!