Ordering something from a marketplace, or directly from a manufacturer, have you ever thought of the way goods pass before they get in your hands? From manufacturing to dispatching, there is a long chain of actions your parcel undergoes to arrive successfully at your doorstep.

Now, just imagine the scale. Millions of people order online every single day from giants like Amazon, eBay, or Walmart. Visualize one of their warehouses: not just shelves stacked to the ceiling, but a vast, buzzing ecosystem of workers, robots, conveyor belts, scanners, and software systems, all working in perfect rhythm. Or at least… that’s the goal.

In reality, warehouses are under constant pressure, which affects their productivity. Orders pour in at unpredictable rates, seasonal peaks push systems to their limits, and even a single mispick can set off a chain reaction of delays.

Bottlenecks creep in: slow inventory updates, misplaced goods, delayed picking, overwhelmed packing stations, and before you know it, the “two-day delivery” promise starts to look shaky.

How to resolve them in one fell swoop and improve warehouse efficiency? Sadly, there’s no magic button, but the right targeted software (or a well-chosen set of tools) can significantly ease the pressure and make your warehouse run far more smoothly. How?

In our new blog post, we dive into proven ways robust warehouse management systems can help, and offer some warehouse improvement ideas to eliminate operational headaches.

Key Highlights

- Inventory bottlenecks are mostly related to data problems: slow updates, mispicks, and lagging synchronization ripple into delivery failures

- Warehouse models diverge by business lines: fulfillment, reverse logistics, cold storage — each demands distinct system logic

- Automation links software and hardware: scanners, robots, and analytics must operate as one real-time control layer

- Forecasting and strategic planning isn’t guesswork. It’s predictive modeling that aligns storage, production, and dispatch to prevent costly downtime

Different Business Lines — Different Processes and Challenges to Overcome

Are all warehouses similar? Not really. Obviously, the main purpose of all warehouses is storage, but here the similarity list might end. Also, as you may have already guessed, the type of software needed and the set of required features directly depend on the kind of business you run and the kind of warehouse you operate.

Third-Party Storage Providers

These are companies whose business is warehousing itself. They rent out space and manage goods for multiple clients, often needing flexible systems to handle very diverse inventories.

Logistics and Transport Hubs

For transportation companies, warehouses are just one piece of a bigger puzzle. They act as transit points where goods are consolidated, stored temporarily, and dispatched via trucks, ships, or planes. Think of them as the beating heart of multimodal delivery networks.

Retail & E-commerce Fulfillment Centers

If you picture an Amazon or eBay warehouse, you’re thinking of this type. Fulfillment centers focus on speed: receiving online orders, picking items, packing them, and shipping them out to customers as fast as possible.

Manufacturing Warehouses

Production companies usually need two kinds of storage:

- Raw materials and components to keep the assembly lines running.

- Finished goods waiting to be shipped to wholesalers, retailers, or directly to customers.

Reverse Logistics Facilities

Returns are a world of their own. Unlike neatly packaged goods on their way to customers, returned items come back in all shapes, sizes, and conditions, from unopened boxes to damaged products. Reverse logistics warehouses need software that can handle unpredictable workflows and a variety of processing rules.

Specialized Warehouses

Some industries demand very specific storage conditions. Here we mean:

- Food & flowers require controlled temperature, humidity, and sometimes even lighting.

- Live goods like lobsters or shrimp may need oxygenation or feeding systems to survive until shipping.

- Medical products often require vibration-free, strictly monitored environments.

- High-value items such as jewelry, precious metals, or even defense-related goods demand top-notch security and monitoring.

As you see, warehousing is far from one-size-fits-all. Different business models, storage requirements, and dispatching workflows all leave their imprint on how operations are structured.

A fulfillment center racing to ship thousands of daily orders faces challenges entirely different from a reverse logistics facility sorting unpredictable returns, or a cold storage warehouse monitoring perishable goods around the clock. These variations mean that bottlenecks also differ, and so do the ways software can resolve them.

Read how we delivered an IoT Solution for Cold Chain Monitoring

What to Automate and Why? Most Bothering Questions to Answer Before You Set to Work

Running a warehouse means taking full responsibility for the goods in storage, knowing exactly where they are, ensuring proper conditions, and moving them in and out quickly and accurately. Manual processes make this task not only slow but also costly, especially in North America, where labor expenses are among the highest operational burdens. From forklift drivers to packers, every hour of manual work adds up, and inefficiencies multiply.

Another crucial benefit lies in proper data management. When every movement, starting from intake and ending up with dispatching, is logged, companies gain a powerful dataset for process optimization. With the help of comprehensive analytics, these data can reveal patterns and suggest improvements: relocating certain goods for faster picking, redesigning storage layouts, or adjusting stock levels.

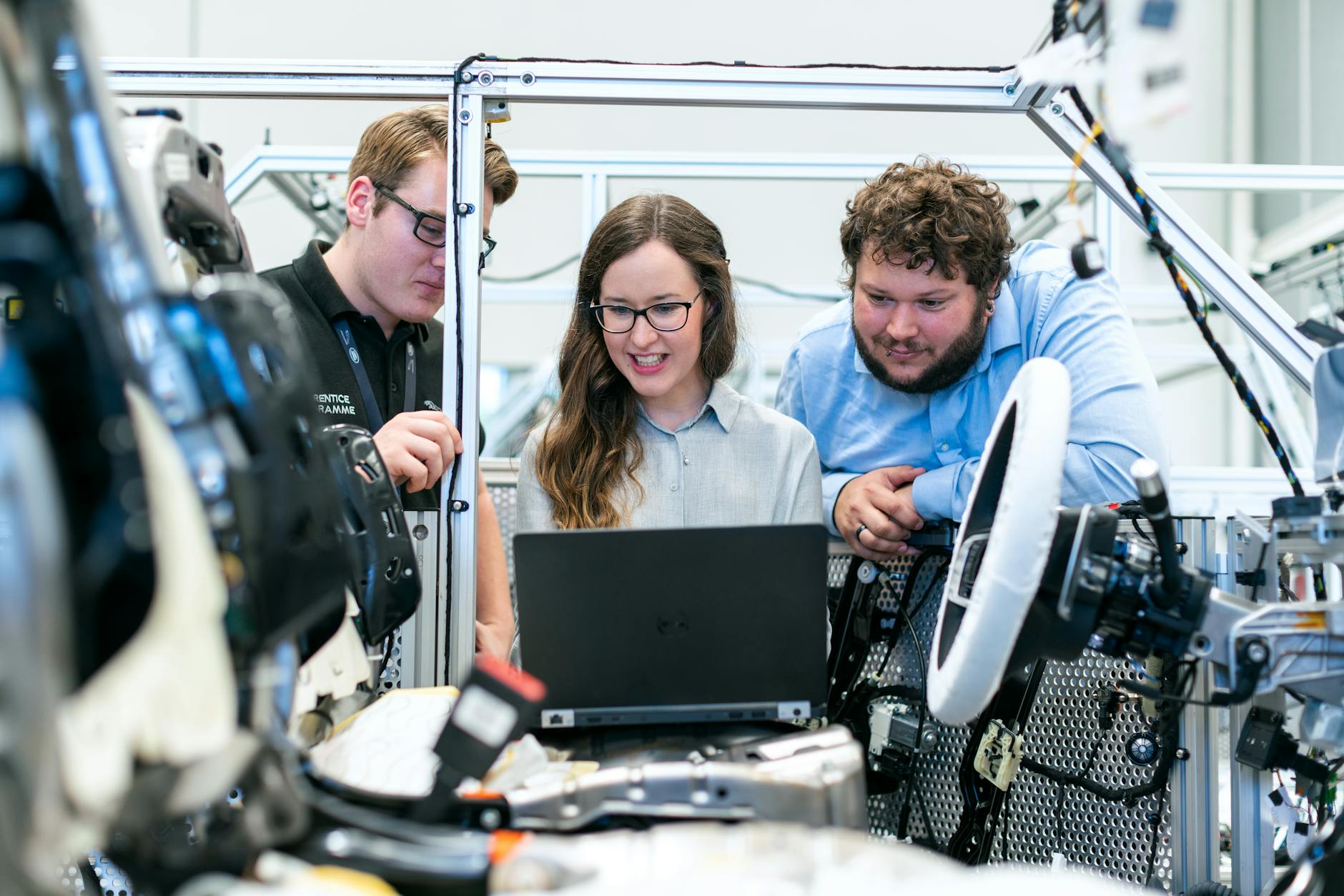

Finally, automation doesn’t stop at software if you aim to improve warehouse performance. Hardware tools like scanners, industrial tablets, printers, and even imaging solutions integrate into warehouse management systems, providing real-time tracking, verification, and labeling. Together, they create a transparent, efficient environment where managers can make informed decisions and ensure smooth operations.

Measuring warehouse performance means looking beyond storage capacity and focusing on warehouse process improvement. The most important factors are order accuracy, inventory turnover, overstock levels, and the ability to prevent bottlenecks that slow down operations.

Equally critical are system reliability and uptime, since even short disruptions can impact delivery schedules and profitability. Modern warehouses also benefit from evaluating how well automation, IoT devices, and management software work together as a real-time orchestration layer. With the right warehouse management system in place, businesses can not only measure these metrics but also drive continuous improvements across the supply chain.

Read about Business Process Automation Strategy and Its Intricacies

Deep Automation and Mechanization. Is it of Critical Need?

While digital tools and workflow optimization already bring significant value, taking the warehouse efficiency management to the next level often requires physical automation and mechanization. A traditional warehouse setup relies on racks, forklifts, pallets, and human labor at intake and dispatch stations. But in highly automated facilities, this picture might change drastically.

Robotics and indoor navigation systems are becoming common. Autonomous robots can move pallets, while wireless tags or camera-based tracking systems allow managers to monitor inventory in real time — not just knowing what’s in stock, but where exactly it is located within the facility. Integration with a warehouse management system ensures that these data are not siloed and are a part of a larger, synchronized control environment.

The vivid example here is our client operating the return logistics business, and our work with them illustrates the shift toward deep automation. Beyond indoor automation, they faced the challenge of managing outdoor trailer logistics. Each of their warehouses had a limited number of loading gates, and trailers had to wait too long at a gate, which entailed costly downtimes.

Together, we explored a solution that uses visual tracking to monitor trailers in the yard, dispatch them dynamically, and ensure gates remain operational. This kind of system bridges the gap between warehouse operations and fleet management, creating end-to-end visibility that extends a bit beyond the building itself.

And that’s exactly the point: modern warehousing doesn’t stop at the warehouse walls. Goods spend a significant amount of time on trailers, often owned by different companies than the trucks that move them. Coordinating these elements requires systems that integrate warehouse management, fleet tracking, and sometimes even external logistics platforms.

Looking to Automate Your Warehouse but Unsure How?

CONTACT US!

The best starting point for automation is the set of repetitive, error-prone, and time-sensitive processes that directly affect delivery speed and accuracy. Receiving, inventory tracking, order picking, packing, and dispatch are usually the first candidates, since even small delays or mistakes here can ripple across the entire supply chain.

Automating these areas with scanners, IoT devices, and an integrated warehouse management system provides real-time visibility and minimizes bottlenecks. Over time, extending automation to predictive planning and returns management unlocks even greater resilience. Prioritizing these core functions ensures a solid foundation and opens up more strategic ways to improve warehouse efficiency.

Types of Systems to Consider for Your Warehouse

Warehousing, as we’ve seen, is rarely just about “putting goods on shelves”. Even within a single facility, the scope of operations can be surprisingly diverse: receiving shipments, inspecting items, handling returns, breaking products into components, or reassembling them into something entirely new.

In reverse logistics, for instance, a single iPhone with a broken screen may arrive at the dock, get disassembled into several spare parts, and later reappear as a completely different unit of inventory ready for resale. In manufacturing, the situation can be even more complex, with countless intermediate storage points for semi-finished goods, components, and assemblies.

This variety inevitably influences the kind of software that companies use to run their warehouses. In practice, warehouse management systems can be roughly grouped into three types.

Off-the-Shelf Solutions

These are ready-made products, often built with specific industries in mind. A pharmacy warehouse, for example, has to comply with strict regulations: certain medicines require controlled storage, expiry dates must be tracked with precision, and security is non-negotiable. For such cases, vendors offer ready-to-use solutions with the necessary functionality already embedded.

Similarly, online retailers that have outgrown Excel often adopt such systems that come with pre-built integrations into platforms like Shopify or Amazon. They are relatively quick to deploy and affordable, but they usually work best for standard workflows. The more a company’s processes deviate from those templates, the more likely it is to hit the limits of such systems.

Configurable Platforms

The second category is made up of universal platforms that you can fine-tune as needed. Think of systems like SAP or Oracle that can be adapted to your business operations. They are particularly attractive for mid-sized and large enterprises, where warehouse processes are too complex to fit into an off-the-shelf solution but not so unique as to demand a system built from scratch.

A car manufacturer, for instance, might need to track hundreds of intermediate flows, from semi-assembled bodies to completed doors waiting to be mounted. A configurable system can be shaped around these workflows, although this pleasure is far from cheap: implementation often takes months or years, requires consultants or dedicated in-house teams, and demands serious budgets. For many businesses, this is the price of scalability and robustness.

Fully Custom Systems

Finally, there is the path of a fully custom system development. This is the choice for companies whose warehouse operations are not just a support function, but the very core of their business model. Our client from reverse logistics is a good illustration: originally a logistics provider for returns, they eventually built their own proprietary software so advanced that it became the heart of their SaaS offering.

Building such a system from the ground up provides unmatched flexibility and the possibility of tight integration with all other internal tools. It can even turn a cost center into a product in itself. But it also means high upfront investment, long development cycles, and the responsibility of maintaining and evolving the system over time.

Explore 9 Key Benefits of Custom Software Development

Forecasting and Strategic Planning. Why It’s Mission-Critical for All Types of Warehouses

An overstocked warehouse is not just about running out of space. It’s the point where finances, production, and risk converge.

Storing goods always comes at a cost. The longer products linger on shelves, the higher the expenses for rent, labor, logistics, and insurance are. At some point, extended storage eats profit margins so much that inventory becomes a liability rather than an asset.

We’ve seen this firsthand with the client we mentioned above. Their business model relied on the fast resale of returned items. To stay profitable, they had to implement predictive pricing models: based on sales history, market trends, and AI-driven algorithms, the system suggested prices that would ensure products sold quickly enough. Otherwise, those items would turn from valuable stock into sunk costs, occupying warehouse space and preventing new shipments from coming in.

Explore how we built a Data Analytics Solution for an eCommerce Company

In manufacturing, the situation is even more critical. When warehouses are full and finished goods can’t be dispatched, production lines may have to stop altogether. For large-scale plants, downtime can cost hundreds of thousands of dollars per day. On top of that, contractual penalties loom if suppliers cannot deliver raw materials because inbound storage is blocked by excess inventory.

This is why warehouse management goes far beyond logistics or business process automation. It lies at the core of strategic planning, tied to pricing decisions, production schedules, and financial strategy. In some cases, calculations show that it’s cheaper to pay a supplier penalty than to overfill the warehouse. In other cases, leadership may decide to build or lease additional storage facilities, and obviously, these investments are quite tangible.

Grasp the importance of Supply Chain Demand Planning and Forecasting

Even at the operational level, warehouse management is about balancing accuracy and costs. For instance, unpacking and counting every item on a pallet may cost more in labor than the potential loss of a single unit. Many businesses, therefore, choose to accept “controlled risks” rather than overinvest in excessive automation and manual effort.

The timeline for ROI depends on the scale of automation and the complexity of your warehouse workflows. For many companies, efficiency gains in picking, inventory accuracy, and order fulfillment start showing measurable results within 6–12 months.

Larger transformations, such as full system integration or robotics, may take longer but deliver greater long-term value. By reducing labor costs, minimizing errors, and ensuring more efficient warehouse operations, automation typically pays for itself faster than expected and continues generating savings year after year.

Robust Risk Management, High Availability, Good UX, and Integration Capabilities as a Blueprint of Your System

Sure thing, overstock or understock is just one drop in the vast ocean of challenges that can disrupt warehouse operations and affect its productivity. Many other issues, such as human mistakes or force majeures, also might cause downtimes, and the aim of technology is to ensure that warehouses can operate non-stop. And the diversity of challenges translates into a set of non-negotiable requirements for any robust warehouse management system.

First, there’s risk management you should keep in mind when improving warehouse efficiency with technology. Complex supply chains mean countless points where things can go wrong — from misplaced goods to human error or even theft.

Modern systems must anticipate these risks, not just record them to increase warehouse efficiency. With AI-driven analytics and automated alerts, a WMS can flag inconsistencies in real time, suggest corrective actions, and even prevent small issues from escalating into operational roadblocks.

Dive into Top Preventive Software Technologies for Supply Chain Risk Management

Another cornerstone is reliability and availability. Warehouses don’t run on office hours: many operate 24/7, with peak loads late at night when goods are prepared for early-morning deliveries. In such environments, even a short outage can lead to catastrophic losses. That’s why architecture decisions, whether cloud-based with redundant connections or on-premises for mission-critical continuity, become strategic safeguards against downtime.

When thinking about warehouse efficiency improvement, also remember about integration capabilities. No warehouse exists in a vacuum: systems must communicate seamlessly with ERPs, logistics partners, or even decades-old mainframes that still power certain operations. Here, real-time data flows are key. Knowing that a pallet is missing right now, not weeks later, can save money, reputation, and customer trust.

Finally, we cannot ignore the human factor. Most warehouses still rely heavily on people — often seasonal staff with minimal training. Interfaces must therefore be intuitive, error-proof, and designed for real working conditions: think large buttons operable with gloves, straightforward workflows, and safeguards against double scans. Training helps, but the best UX design ensures that even an exhausted worker at 3 a.m. can’t go wrong.

Find out how we created a UX-Friendly Data Analytics Solution for an Oil Producer

Conclusion

Warehousing is a complex ecosystem where efficiency depends on far more than just storage space. From overstock risks and unpredictable returns to regulatory compliance and the need for seamless integration, challenges are both diverse and ever-changing. What unites them, however, is that none can be solved effectively without technology.

Robust warehouse management systems, whether off-the-shelf, configurable, or fully custom-built, serve as the backbone that keeps operations synchronized, resilient, and cost-effective.

Building valid warehouse management software takes both tech expertise and industry insight. At Velvetech, we’ve delivered solutions that improve operations, cut downtime, and turn warehouses into growth drivers. If you’re looking for a reliable partner to transform your warehouse operations, we’re here to help you make it happen!