Businesses that require smooth logistics, inventory coordination, and supply chain management often face the question: do it all alone or turn to providers? That’s food for thought.

Generally speaking, there are several options to choose from. You can totally do it with your resources and, for example, employ business process automation to simplify the workflow. It’s also a wise move to build a robust 3PL solution that can seamlessly handle key logistics operations.

Alternatively, you may choose to manage some of the supply chain tasks alone and reach out to providers to take the rest. Eventually, you may entirely lean on providers to elevate and optimize your supply chain management.

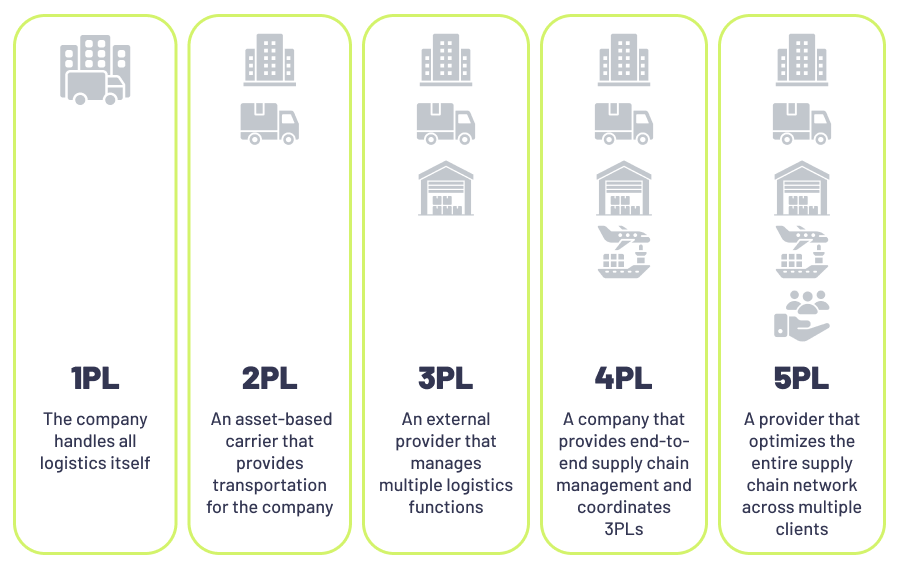

Generally speaking, there are five types of logistics models to consider. Which one to choose depends on your business size and end goals. So, let’s dive in and see which approach could be the right fit for your endeavor.

Key Highlights

- 2PL is best suited for companies that handle their supply chain processes internally and want to outsource their transportation solely.

- With a robust 3PL solution in place, businesses can automate main logistics functionalities and focus more on their core business strategies.

- 4PLs manage the client’s entire supply chain and are responsible for engaging with multiple 3PL operators and other logistics providers.

- While 4PL offers a holistic approach, from sourcing and procurement to distribution and delivery, it highly increases your dependency on the provider.

From 1PL to 5PL: Navigating in the World of Logistic Providers

When it comes to logistics providers, probably 3PL instantly comes to mind. Yes, this model is quite familiar to many businesses. But as we’ve mentioned, you actually have up to five options. So, let’s briefly skim over each:

Understanding 1PL

The first logistics model on our list is 1PL. It is best for small manufacturing businesses that handle all their operations alone, from inventory management to transportation and reverse logistics.

1PL is the only model where no intermediary takes part in the operations. That means there are only two parties involved: the business and the client. Typically, businesses choosing first-party logistics employ automation to increase the productivity of their operations.

Discover key Tasks to Automate in Your Manufacturing

When to Use 2PL

While you chose to handle a hefty dose of your supply chain external processes alone, you may need some help to organize the delivery process. This is where second-party logistics steps in. It’s an intermediary company that optimizes transportation operations.

Generally speaking, as a client, you may also expect from 2PLs to provide route optimization and real-time tracking to ensure fast and safe deliveries. Especially, if you trust the transportation of pharmaceutical or perishable goods.

To get there, 2PLs typically leverage IoT devices, GPS tracking, and transportation management systems.

Learn more about how to elevate logistics with Trucking Dispatch Software

When 3PL Steps In

Transporting goods is a drop in the bucket in the supply chain. Many other processes, such as stock planning, warehouse management, and reverse logistics, require your attention. And that’s where 3PLs come into play.

See how we improved the client’s Warehouse Management Operations

Simply put, compared with 2PLs, third-party logistics providers handle more tasks, thus noticeably simplifying entire supply chain management. All technologies of 2PL are applicable to 3PL as well. Plus, here you can see more often picking and packing robots, WMS, TMS, sorters, conveyor belts, artificial intelligence, robotic process automation, etc.

Overall, 3PLs can turn out to be highly beneficial for mid-size and large businesses that want to offload some logistics functionalities and be more focused on their core business strategies.

Leverage warehouse management software development

TALK TO USWhat 4PL Is All About

When it comes to collaborating with a 3PL, you ideally need to pick the best provider from the thousands of existing options. Besides, you need to stay in constant communication with them. Not the simplest process, right? In addition, it’s pretty time-consuming.

And, probably, you can guess that it will be twice as difficult for companies with complex supply chain operations that need to partner with multiple 3PLs.

What if we say that fourth-party providers can handle this for you? Well, 4PLs take over the client’s entire supply chain management process, including coordination of multiple 3PL operators and other logistics providers.

In addition, 4PLs offer a wide range of strategies to optimize the supply chain. To do this, they typically rely on different types of AI, ML, big data, and predictive analytics.

Given the aforementioned, it’s pretty safe to say that in comparison to 2PL vs. 3PL vs. 4PL, the latest option definitely wins for large enterprises.

What to Expect from 5PL

This is a relatively new model. 5PL is like an advanced level of 4PL that offers more sophisticated supply chain optimization. 5PLs efficiently manage a wider supply network, rather than focusing solely on the individual supply chain. Overall, 5PL aims to cater to the comprehensive needs of eCommerce, which makes fifth-party logistics a precious asset for businesses with no physical presence.

Compared with other logistics models on our list, 5PLs can integrate more progressive technologies like blockchain solutions and advanced data analytics. And like 4PL, this model also offers supply chain optimization plans and IT consulting. Plus, it provides project management services. As a result, 5PL becomes capable of handling highly complex supply chains.

Dive into the nits and grits of Effective Supply Chain Data Analytics

Both 4PL and 5PL work best for industries with complex and global supply chains that deal with multiple suppliers and large-scale distribution networks. In fact, almost every sector has brands that operate globally or internationally.

Below are the most prominent industries that can benefit from 4PL and 5PL:

• Manufacturing

• Retail and eCommerce

• Electronics

• Energy

• Automotive

• Pharmaceuticals and Healthcare

• Food and Beverage

• Fashion and Luxury Goods

We’ve highlighted the five models along with their core functionalities. Now, you have a solid understanding of their differences and can assess their benefits for your current business operations. Below, we’re dropping this comparison table in case you’d like a quick overview of each one once more.

Logistics Provider |

Description |

Scope |

Complexity of Supply Chain |

Scalability |

|---|---|---|---|---|

| 1PL | A company that handles all logistics using its own resources | Inventory, transportation, and reverse logistics | Simple | Limited to in-house resources |

| 2PL | Provides transportation services to manufacturing companies | Transport products from warehouses to customers | Low to medium | Can scale with growing transport needs |

| 3PL | Provides comprehensive logistics and supply chain operations | Inventory and warehouse management, picking and packing, shipping, and reverse logistics | Medium | Highly scalable and suits mid-size to large businesses |

| 4PL | Manages the entire supply chain for a client | Entire supply chain management, coordination of multiple 3PLs, and supply chain optimization | High | Highly scalable and can meet the needs of large multinational companies |

| 5PL | Manage and optimize a wider supply network | Maintenance of the entire ecosystem of supply chains | Very high | Extremely scalable and can fit the needs of global enterprises |

3PL vs. 4PL: Which One Wins for Your Business

By now, you’ve gained a solid grasp of different logistics models. And now, you can better picture which one can best cater to your business’s specific needs. Typically, the choice comes down to 3PL or 4PL.

These two are among the most in-demand models. However, in some cases, 3PL and 4PL may look a bit similar, hence it can turn out to be challenging to understand which one you really need. Let’s have a look at examples to sort things out.

Consider you run a local eCommerce business. You need smooth order fulfillment, reliable delivery, and efficient returns handling. On top of that, you seek a solid inventory management system to elevate supply chain demand planning and forecasting. In this case, a third-party logistics provider can be very helpful. Yet, the choice isn’t always black and white.

See how we crafted a robust Inventory Management Software for a Client

You could efficiently organize all product orders with an eCommerce solution in place. Alternatively, you could opt for end-to-end 3PL software to automate many processes from inventory management to delivery. So, the choice is yours: develop your own enterprise solution or rely on a logistics partner.

Discover the top Benefits to Reap from 3PL Automation

You see, 3PL works best for businesses that need to outsource only some logistics functions. But what if you need more in-depth assistance to optimize and manage your entire supply chain? In this case, 4PLs save the situation.

Picture having an eCommerce business with multiple stores across different regions. So, here you should manage multiple providers and analyze the overall performance of your supply chain to optimize it. Plus, you should be cautious not to overlook the local laws and regulations, which, of course, may differ from your region.

This can be quite challenging. And here, turning to 4PL will be a wise move. It will seamlessly integrate 3PLs and assist in streamlining your operations.

If you require a relatively small supply chain, then you can initially start with 3PL. But over time, as your business grows, you may need a more robust supply chain management system (e.g., international coordination, multi-country shipments, and multiple suppliers management).

If so, it’s probably time to switch to 4PL, allowing logistics providers to ensure your business operates smoothly and efficiently across different regions.

We’ve explained the differences between the most common logistics models. But before wrapping up, let’s also share a list of advantages and pitfalls you should be on the lookout for before employing 3PL and 4PL in supply chain management.

Pros of 3PL

- Increased productivity: 3PLs leverage advanced technologies, which noticeably elevate the productivity of business operations and reduce time spent on logistics tasks.

- Cut costs: When you don’t need to organize all transportation, warehousing, and hire staff to handle those operations, you significantly cut labor and operational costs.

- Scalable: Whether you choose 3PL providers or solutions, they can easily scale with your business growth.

- Focus on strategic tasks: Again, whether connecting with providers or having a 3PL platform that automates plenty of tasks, it saves you precious time to focus on your business strategic growth.

Cons of 3PL

- High upfront costs: An initial partnership with a provider may be pretty costly due to setup costs. Creating your own 3PL solution is not going to be a cheap pleasure either.

- Less control: If you decide to go with providers, then you will have less control over logistics processes.

- Limited strategic input: 3PLs provide logistics services only. They do not create supply chain optimization plans or offer advice on improving performance or overall strategy.

Pros of 4PL

- End-to-end supply chain optimization: From sourcing and procurement to distribution and delivery, 4PL offers a holistic approach.

- Strategic management: Aiming to elevate the performance of the supply chain and optimize it, 4PLs create a strategy to improve efficiency and streamline processes.

- Consultative approach: 4PLs include consultative services to help businesses improve their performance and meet their end goals.

- Technology-driven: Given all the benefits 4PL offers, you can probably guess that it relies on advanced innovations such as AI, ML, IoT, big data, RPA, and the like to get things done.

- Scalability: Your business growth is not a problem for a 4PL. That is to say, it can seamlessly handle the evolving needs of your business.

Cons of 4PL

- High dependency: Given that a 4PL manages all aspects of your supply chain, including coordination with 3PLs and other providers, your business is relying heavily on fourth-party providers.

- Integration complexities: 4PLs serve as a bridging gap between clients and providers. To get there, it should align systems between the two parties, which is not a walk in the park.

- Expensive: Considering the range of services 4PLs offer, be prepared to dig deep into your pockets.

Given that a 3PL handles some logistics functions while a 4PL takes on the responsibility of managing and optimizing the entire supply chain, the latter comes with a higher price.

The current budget of 4PL services will depend on the functions you require (e.g., handling procurement and sourcing or managing vendors). Additionally, 4PL provides consultation, which is also a valuable service. These factors make 4PL more costly, but at the same time, it can generate a higher ROI.

Choosing the Relevant Logistics for Your Business

When it comes to elevating logistics services to streamline the entire supply chain, many businesses face a question: build a robust custom solution or collaborate with logistics providers.

The choice heavily depends on your business size and main goals. In this publication, we skimmed through five logistics models and explored their key capabilities to help you better grasp which could be the best match for your endeavor.

Alternatively, we discussed cases when crafting your solution is a wise move. If you go with providers, choose ones with proven expertise in your niche. If you decide to get things done with your software, collaborate with a trustworthy vendor.

Whether you aim to build a solution from scratch or add technologies to elevate its performance, we’re ready to turn your project into reality. Trust the decades of our experience in delivering supply chain software services and building 3PL systems.