- Project: Shipping software development to support logistics operations

- Duration: 10 months

- Technologies: AWS IoT Core, Amazon DynamoDB, AWS Lambda, Embedded C++, FreeRTOS, 4G / LTE, MQTT, BLE

The Client is an international company providing services in the transportation and logistics sector. Their core business operations include shipping, port operations, supply chain management, and warehousing.

THE CASE

The company involved our team to help develop a comprehensive solution that will optimize their supply chain efficiency and improve the integrity of shipped goods. They were looking for a modern system built in shipping containers to support real-time location tracking. On top of that, it was essential to monitor such critical parameters as temperature and humidity.

The Client’s Request

What is one of the most substantial things in the logistics and supply chain sector? Well, our Client would say that it’s maintaining product integrity while in transit and ensuring it reaches its final destination in time and in excellent condition.

With so many factors impacting shipments and a huge number of transported goods, it becomes challenging not only to avoid loss and the deviation in actual delivery time but also to provide a perfect environment during transit. That’s why the company decided to leverage the development of custom logistics software for tracking both location and conditions.

Like the Client itself, Velvetech cares about the quality of delivered services and results. Furthermore, we already had implemented a similar project, designing a robust solution for cold chain monitoring to keep perishable goods safe. Since our values and experience matched what the company was looking for, we stepped into the game to deliver part of the project and bring in our expertise in embedded software development.

Read about the Development of an IoT System for Cold Chain Monitoring

Process

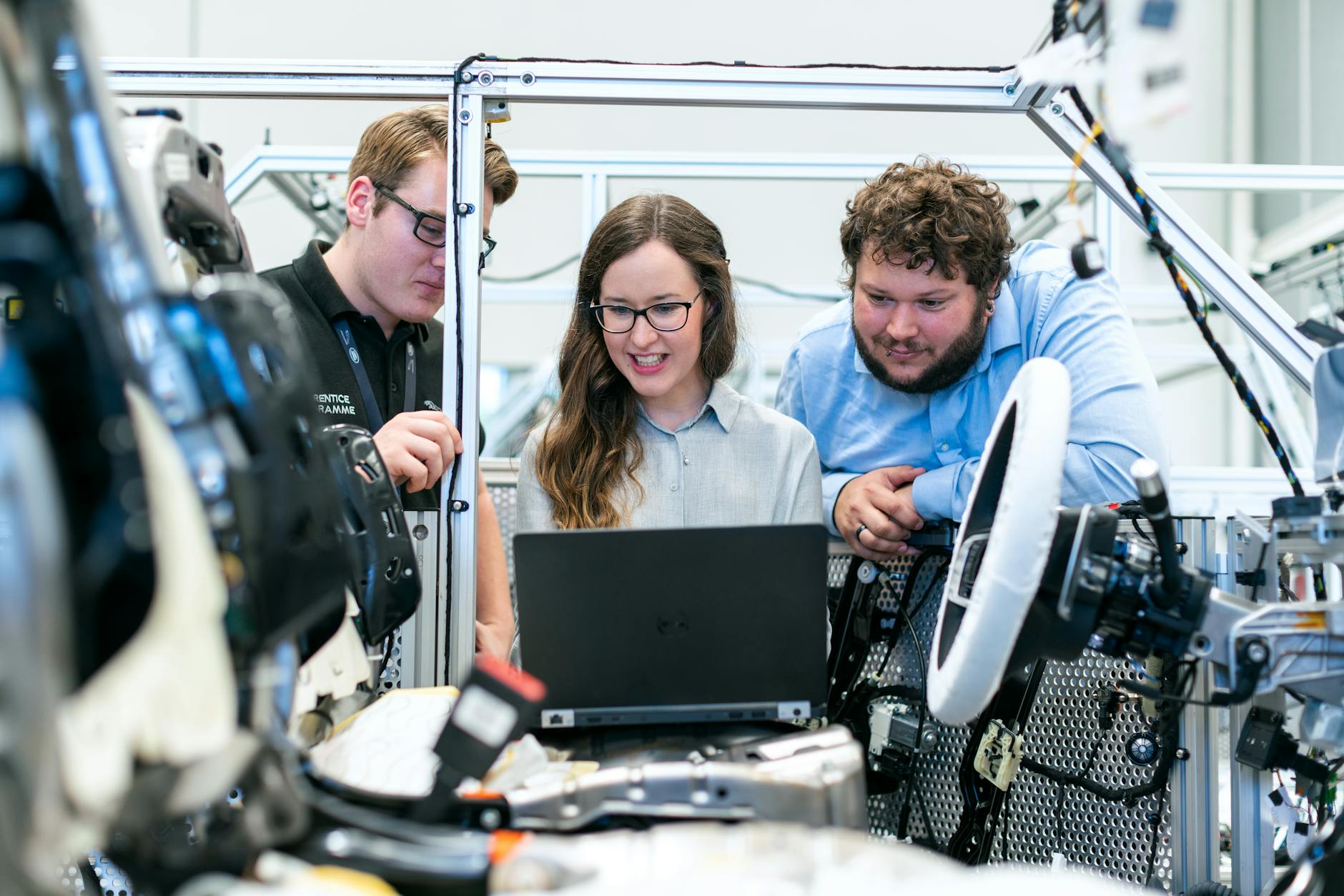

Before providing a scope of work and a detailed project roadmap, our team, as usual, conducted thorough research and analyzed the requirements during the discovery phase. AAt this business analysis stage, our specialists closely collaborated with the Client’s team to validate the idea, set achievable milestones, and define potential bottlenecks.

As a result, we proposed to build a shipping tracking system made of several vital components. The first one was implementing firmware to set up a smooth process of collecting location, temperature, and humidity data. Then, it was essential to organize this data’s storage and processing, which is hardly feasible without cloud integration. Finally, given the environmental conditions during shipping, we had to ensure a stable infrastructure.

Overall, the project was divided into three main parts:

- Development of a sophisticated bootstrap module

- Integration of firmware with the AWS cloud platform

- Provisioning of a scalable environment

Bootstrap Module Development

As part of firmware development, Velvetech was working on delivering a bootstrap module. It’s responsible for setting up hardware configurations, initializing memory, and starting the execution of the main firmware code. Particularly in this project, it played a crucial role in initializing and configuring the firmware on the devices within the shipping containers.

The overall functionality and reliability of the firmware significantly depended on how well went the implementation of this module. Our team put their skills into the robust coding of this bootstrap component to ensure a streamlined and secure start-up process, which laid the ground for efficient data collection and transmission.

AWS Cloud Integration

For effective operation, the entire solution required a stable and scalable infrastructure. Nowadays, it’s nearly impossible to achieve it without cloud computing. As many projects we deliver involve working with cloud providers, our team is an old hand at setting up cloud infrastructures.

Thus, moving on to the next step of the project, we seamlessly integrated firmware with Amazon’s cloud services, a provider our Client trusted. Such integration allowed for secure storage, processing, and analysis of data that is generated in real time. On top of that, leveraging AWS’s capabilities ensured the solution’s high accessibility — a critical factor for a global logistics network.

Environment Provisioning

Finally, since containers — and so the firmware — face diverse environmental conditions during shipping, it was essential to consider that while implementing the solution. With that in mind, our team came up with adaptive algorithms programmed to recognize and adjust to varying temperatures and humidity.

Having long-term experience in hardware engineering, we also helped the Client verify that the firmware was compatible with the hardware components within the shipping containers. This included setting up sensors for temperature and humidity monitoring, defining thresholds for corresponding alerts, and configuring communication protocols.

This approach enhanced the overall efficiency of the tracking and monitoring system and ensured that it remained accurate under different circumstances. Ultimately, it helped prevent false alarms or inaccuracies in data readings that could happen if the system were configured rigidly.

Challenges

The goal was to build a global container tracking system that could support connectivity in remote areas. One of the ways to achieve that was by implementing a fallback mode of satellite communication. This supported uninterrupted data transmission even in regions with limited network coverage.

On top of that, it was crucial to optimize power consumption, given the extended duration of some shipments. While working on this task, our team developed efficient algorithms that helped manage power usage intelligently. They aim to extend the lifespan of device batteries and reduce the need for frequent replacements.

Outcome

While the company was predominantly looking to drive real-time tracking and monitoring of transported goods, the acquired solution led to improvements in three major areas:

- Supply chain management

- Quality assurance and compliance

- Decision-making process

Advanced firmware enhanced the Client’s supply chain visibility. With the real-time tracking system, the company’s team can proactively address any potential issues and minimize delays, not to mention boost operational efficiency.

As planned, the solution helped improve the integrity of sensitive cargo, which allowed the company to ensure they met regulatory compliance and quality assurance standards. It also contributed to their clients’ satisfaction and mitigated the risks related to damaged products.

Lastly, there was a lesser expected outcome the Client achieved as a bonus. The cloud integration provided a centralized platform not only for data storage but also for effective data analytics. This naturally empowered the company with actionable insights and supported informed decision-making for continuous process improvement.

Our specialist will contact you to schedule a personalized consultation within one business day.

Velvetech offers complimentary consultations; after which, we will provide you with a proof of concept in just 3 days, an accurate outlook of the cost and timeline of your project and a competitive estimation, and an assembled team – ready to start your project within 7 days.

Proof of Concept in

Start Project within