It started with a familiar winter mistake: forgetting to shut off the outdoor valve before the freeze. But this time, instead of another warning email, a product team asked: What if the valve shut itself off? What if it warned you before your pipes froze? What if it could connect to your smart home ecosystem?

They had the vision, followed by a rough prototype. But to build something truly compact, waterproof, and ready for market, they needed the right IoT development partner.

That’s the story we’d like to share today, hoping that it can inspire you to initiate your project and turn vision into reality.

When a Bestseller Meets a New Frontier

The company’s core valve was a consistent top seller. Yet, the world doesn’t stand still, and to navigate new territories, the company needed to add smart capabilities.

What they had was a promising idea and a clunky prototype to show for it. The device, pieced together with off-the-shelf components, was large, fragile, and far from consumer-ready. Inside the company, no one had hands-on experience with PCB design, embedded firmware, or mobile app development.

Furthermore, the team wasn’t even sure how or whether at all the product should integrate with existing smart home systems.

And with no clear sense of demand volume and a budget that left little room for missteps, they couldn’t afford to charge ahead blindly. They needed a way to innovate with precision: fast, focused, and without overextending.

From Concept to Clarity: A Strategic Collaboration

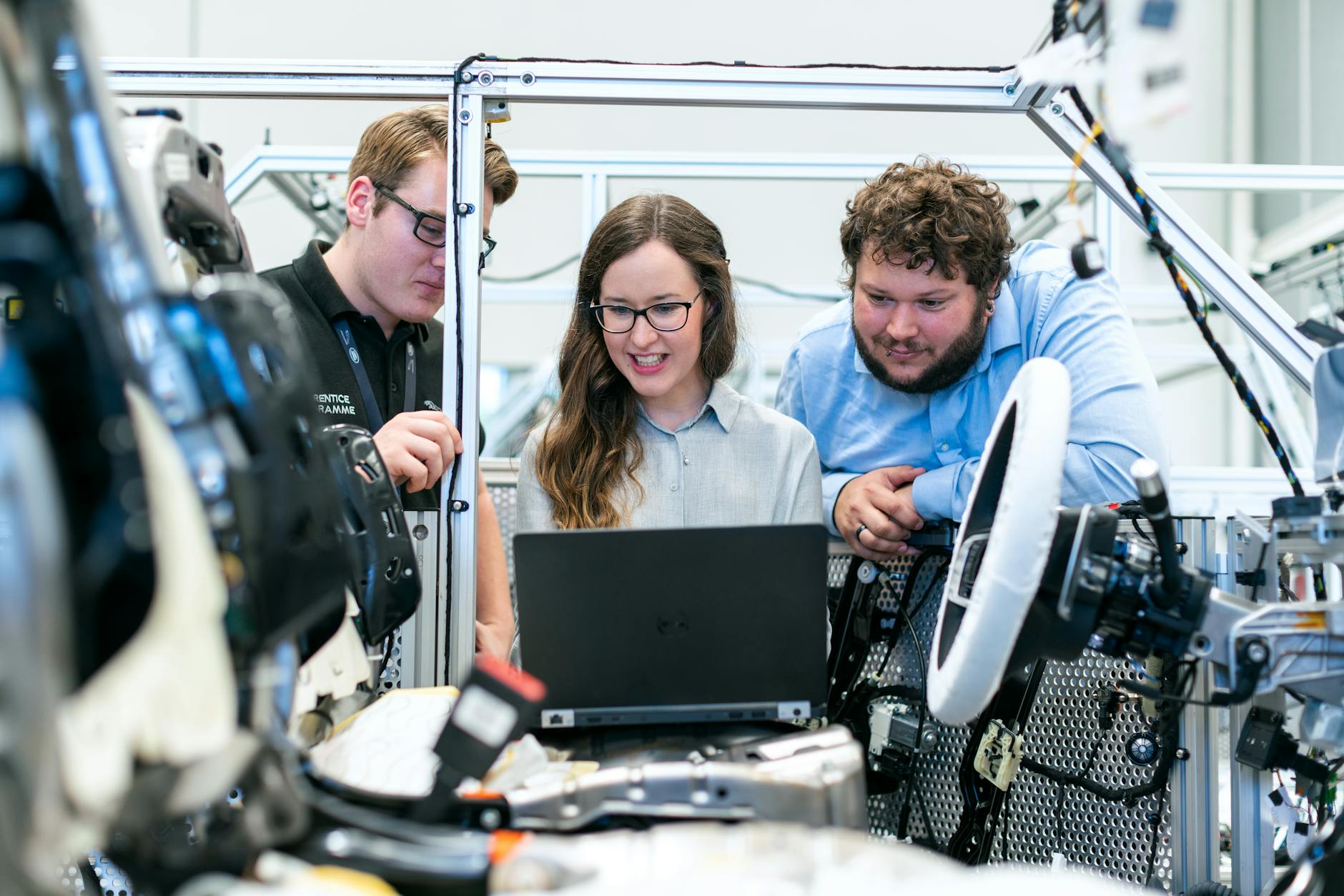

Velvetech was brought in not just to “build the thing,” but to co-engineer the future of the product, step by step.

Setting the Stage

When our hardware engineers got their hands on the early prototype, it was clear the concept had potential, but the execution needed work. The device was clunky, cobbled together with off-the-shelf parts, and far from ready for outdoor use. So, we got to work.

First, we traced how the internal components could be consolidated to reduce the device’s size without compromising functionality. Then we looked at battery performance and waterproofing, crucial for something that would spend winters braving the elements.

We also drew a clear line: which components could remain off-the-shelf to save time and budget, and which parts needed custom design to meet long-term goals. The outcome was a focused plan to evolve the prototype into a real product, one smart decision at a time.

Turning Ideas into Something You Can Hold

With the plan in place, it was time to bring the physical product to life. Our engineers reimagined the hardware, trading makeshift bulk for compact efficiency.

They designed a custom PCB using vertical stacking to pack more functionality into less space. Every component was selected with real-world durability in mind, able to withstand harsh temperatures ranging from -10°F to 110°F. Power was flexible too: customers could go rechargeable or swap batteries once a year.

All of this fits inside a tough, sub-3×3-inch enclosure, rated IP65 to survive rain, dust, and everything in between. Finally, the device was starting to feel like a product.

Connecting Without the Complexity

Connectivity was next, though we didn’t rush into bells and whistles. Instead, we focused on what would work now and scale later.

Wi-Fi was the clear choice for early adopters, offering simplicity and reach. While we left the door open for ZigBee down the line, we steered clear of costly BLE hubs or proprietary protocols that could complicate the MVP.

Learn more about Killer MVP App Development

Then came a smart safeguard: a supercapacitor-based backup system that could trigger valve closure even in a power outage.

Launching Smart, Scaling Right

We’ve seen it before: companies sinking their budgets into flashy apps no one really uses, and, of course, we didn’t want that here.

So instead of building a custom app from scratch, we recommended starting with a proven smart home platform like Smart Life. It offered a fast, affordable way to get into users’ hands without starting from zero.

Custom app development? That could come later, once demand was proven and the user base was ready. Until then, we focused only on the must-have features that would deliver value from day one.

Find out How to Prioritize MVP Features

The Business Payoff: More Than Just a Prototype

By the end of our collaboration, the client walked away with a working MVP. Moreover, they had a real launchpad.

The company now had a clear, scalable roadmap showing exactly how the product could evolve. With development phased deliberately, early costs stayed in check without sacrificing future potential. The combination of smart hardware and third-party software meant they got to market faster and smarter.

Behind the scenes, everything was built with the next steps in mind: certifications, integrations, and eventual expansion. And when it was time to scale internally, their team had full documentation, technical guidance, and a product they truly understood.

Discover the Ultimate To-Do List for a Successful IoT Project

Got a Smart Idea Stuck at the Starting Line?

If you’re holding an early prototype or just an ambitious napkin sketch, you don’t need a vendor. You need a co-creator.

Whether you’re making smart valves, thermostats, or anything in between, Velvetech helps you bring IoT products to life with precision, flexibility, and budget-conscious execution. Start your IoT journey with a no-pressure discovery call.