Businesses that deal with trade, imports, exports, storage, or shipments need to properly manage inventory, fulfillment, and logistics. Such companies exist in every industry, from eCommerce and manufacturing to healthcare and hospitality.

But let’s face it, establishing robust logistics and supply chain management processes is not that straightforward. Handling them manually can turn out to be quite time and resource-intensive. And no business really wants to carry that burden. Fortunately, there is one foolproof solution for them: third-party logistics software.

Key Highlights

- End-to-end 3PL covers the entire supply chain process from inventory management and order fulfillment to transportation and reverse logistics.

- Depending on the business’s specific needs, there are three different levels of 3PL automation to consider: low complexity, medium complexity, and high complexity.

- 3PLs use innovations like automated guided vehicles and conveyor systems to move heavy items through warehouses, thus significantly reducing the injury risks of employees.

- By using autonomous robots, electric vehicles, optimizing delivery routes, and ensuring eco-friendly packaging, 3PL systems help minimize carbon footprints.

In general, this technology makes many complex tasks hands-free, from product picking and packing to shipping and reverse logistics. To achieve this, 3PL platforms integrate hardware like robotics, fleet telematics devices, etc. with software such as warehouse management systems, supply chain platforms, logistics solutions, etc.

Now, let’s dig deeper and discover more interesting ground about automated 3PL solutions.

From Simple to Advanced: Different Levels of 3PL Automation

In general, businesses may opt for a 3PL solution to fully manage their logistics and supply chain operations or to automate some of the processes.

For example, a mid-size retail business may simply manage order processing and check stock availability through its eCommerce platform, but chooses not to tap into the heavy lifting of reverse logistics. Instead, it may employ automated 3PL systems to do all the hard work from transporting returned items to warehouses to clarifying what to do with them according to documentation (resell, repair, send to the vendor, or dispose).

In comparison, a big retail business may require end-to-end 3PL automation. In this case, third-party logistics automation handles all operations from order fulfillment and inventory management to transportation and reverse supply chain.

You see, depending on your business end goals, you choose what kinds of 3PL automation to employ. Overall, there are three levels of automation in third-party logistics operations. Let’s briefly go over each:

- Low Complexity: A simple 3PL warehouse automation. Typically, operates independently with minimal interaction with advanced systems. The main goal is to make basic warehouse operations and data entry hands-free.

- Medium Complexity: Integrates with different systems to ensure smooth data flow. Includes technologies like automated storage and retrieval systems, parcel sorting systems, predictive analytics, etc.

- High Complexity: Considered a high level of interoperability across diverse systems. Employed advanced solutions like automated guided vehicles, robotic pickers, autonomous mobile robots, and smart shelves to streamline human–machine collaboration. Ideal for big warehouses.

End-to-end 3PL is all about efficiently managing the entire supply chain process. It’s most common for large businesses, which prefer to trust the hard logistics operations to the 3PL companies. Here is what to expect from end-to-end 3PL:

• Robust inventory management

• Comprehensive order fulfillment

• Smooth transportation

• Seamless reverse logistics

The Value 3PL Automation Brings to Business

The global trade management market is constantly growing and is expected to reach $1.3 billion by 2027. The eCommerce market isn’t staying apart either. It’s projected to hit an impressive $83.26 trillion by 2030. And to remain competitive, businesses, of course, will continue heavily relying on robust 3PL solutions.

Meaning, the demand for automated 3PLs will keep growing steadily. So, let’s break down what exactly makes this technology all the rage.

Increased Productivity

As we’ve already mentioned, one of the main reasons to employ 3PL automation is to optimize many time-consuming business processes. As a result of 3PL software deployment, there are far fewer errors compared to manual interaction. This, of course, noticeably increases the productivity of business operations. Overall, 3PL systems are capable of automating almost everything. It all depends on current goals and the specific needs of the business.

Learn more about the key Benefits of Business Process Automation

For example, you can consider 3PL warehouse management billing automation to streamline invoicing. Alternatively, you may employ 3PL fulfillment automation systems to enable faster and more reliable order processing. Eventually, you may require all the things mentioned above and more to elevate the productivity of your warehouse operations.

Discover how we helped the client to Elevate Warehouse Management Operations

Cut Costs

Besides merely elevating productivity by reducing manual errors, 3PL automation also noticeably cuts costs. Just consider how many tasks tech solutions can handle. Probably pretty much. On top of that, third-party logistics solutions can cut down on operational costs.

For example, you can significantly optimize transportation operations with the help of 3PL automation. In particular, it can track traffic in real time and offer optimized routes. Thus, reducing both delivery time and fuel consumption.

Check out the must-have features of a robust Trucking Dispatch Software

Improved Inventory Management

Probably, achieving robust inventory management is not an easy nut to crack. First and foremost, you should ensure all products are stored in accordance with their specific requirements for storage and placement. Plus, you need to know the amount of your goods in warehouses to avoid overstocking and understocking.

And the good news is that automated 3PL systems can seamlessly provide real-time data on inventory levels and current orders. Additionally, third-party logistics solutions are capable of tracking the specific conditions needed to store products.

Find out key ways to Elevate Stock Planning With Data Analytics

Enhanced Workplace Safety

Automated guided vehicles, robotic arms, and conveyor systems are just a few technologies 3PLs employ to carry heavy goods. Meaning there is no need to manually move large, heavy, and sometimes dangerous items. This minimizes the risk of serious injuries and incidents, leading to safer workplaces.

Undeniably, this increases employee satisfaction as well. And really, who doesn’t want to feel safe in the workplace?

3PL software that offers robust automation capabilities can bring plenty of benefits to businesses of every size and niche: Specifically, it will:

• Increase productivity

• Reduce costs

• Provide better visibility and control over inventory

• Elevate workplace safety

Behind the Scenes: Technologies Driving 3PL Automation

It’s already clear that 3PL solutions have become a treasure trove for businesses, taking the burden of supply chain management off their shoulders. So far, we’ve highlighted what third-party logistics automation can bring to the table. Now, let’s take a look at the technologies acting behind the scenes.

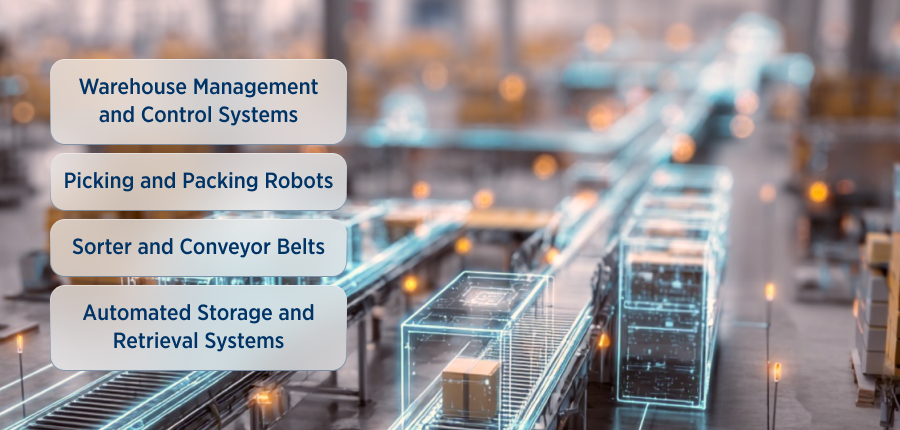

1. Warehouse Management and Control Systems

Both warehouse management and control systems aim to streamline inventory management, storage, and overall workflow. The first one provides insight into the integrity level and notifies in case of restocking. As for the second one, it ensures safe and fast movement of goods through warehouses.

2. Picking and Packing Robots

3PL automation can be pretty useful to speed up and simplify the picking and packing process. For example, it employs robotic arms to take items from storage and pack them according to their specific requirements. After that, mobile robots transport the goods to the required location for shipping. Here is the outcome this automated equipment does for 3PL:

- Faster processing

- Lower costs

- Higher accuracy

3. Sorter and Conveyor Belts

Generally, items are sorted in the warehouse depending on factors like size, weight, and type. Sorters and conveyor belts are technologies that automate the movement of items and send them to the relevant storage areas based on the above-mentioned criteria.

4. Automated Storage and Retrieval Systems

Probably, AS/RS is a treasure trove for high-volume warehouses where space optimization is pretty crucial and challenging. Overall, these solutions act as smart warehouses where automated shuttle vehicles or cranes transport and store goods.

These are the top technologies included in 3PL automation. Depending on your business goals, you can choose one or a couple of them. Alternatively, if you’re thinking about end-to-end 3PL, then you’ll likely need to include all of them along with some additional functionality.

That said, enterprise solutions might serve you best. Plus, since most of them rely on cloud computing today, you can scale your product up or down instantly and cost-effectively.

Depending on your business objectives, there are different 3PL automation solutions to consider. The core ones are as follows:

• Warehouse management and control systems

• Robotic picking solutions

• Sorters and conveyor belts

• Automated storage and retrieval systems

What Makes 3PL Automation Trendy?

With so many things being said, you see how important 3PL automation is for business. But before wrapping up, let’s also highlight the top three trends of 3PL automation, making it a desirable chase for businesses of different sizes and niches.

Human-Robotic Collaboration

The word automation used to be seen as a double-edged sword. On one hand, it simplifies many routine tasks, but on the other hand, it was considered a tool that would replace people. However, today we see humans and machines starting to collaborate.

3PL automation is one of the perfect examples of this. While robots handle repetitive tasks and carry heavy items, humans can focus on more important tasks and strategic planning.

Data-Driven Logistics

Today, ensuring fast and safe delivery is one of the key goals of businesses. This is mainly because customers today prefer to receive their goods as soon as possible, and of course, as safely as possible. To achieve this, 3PL automation solutions employ plenty of innovations.

For example, they leverage automated inventory management systems to track stock levels and IoT sensors to monitor product conditions in warehouses and during transportation. In addition, 3PL automation solutions employ AI algorithms to track delivery progress and identify the best optimized route.

Find out why IoT Is a No-Brainer For Transportation and Logistics

Sustainability-Driven Automation

If you aim to minimize your carbon footprint, then 3PL systems can be pretty helpful. We’ve already mentioned the automated technologies 3PLs utilize, like autonomous robots and electric vehicles. Plus, 3PL optimizes routes for delivery, leading to less fuel consumption.

In addition, 3PL systems can identify the most efficient packaging for each product, thus making the packaging not only safe but also eco-friendly.

Discover How IIoT Can Help You Surpass Environmental Goals

Managing All Logistics Operations In One Place

From inventory management and order fulfillment to shipment and reverse logistics, automated 3PL systems can truly assist at every stage of the supply chain. But to reap all the benefits of 3PL automation, you first need to implement the right technologies. Given the complex nature of logistics, it’s clear that this is far from straightforward.

If you are currently looking for a trustworthy vendor to collaborate with, let Velvetech bring its 20+ years of logistics experience to your venture.

Whether you want to optimize the performance of your existing system or build a new one from the ground up, we’ll be happy to assist. Let’s get in touch.